Discover Precision with Five-Axis Machining

Experience unparalleled precision and efficiency with our Five-Axis Machining Center, designed for high-speed, accurate production in aerospace and mold processing industries.

Enhance Your Production Capabilities

Our machining center integrates seamlessly into automated production lines, offering flexibility with multiple tool magazine options and high-speed spindle design.

Precision and Efficiency Redefined

Achieve industry-leading accuracy with our machine's compliance to VDI/DGQ 3441 standards, ensuring reliable performance in every operation.

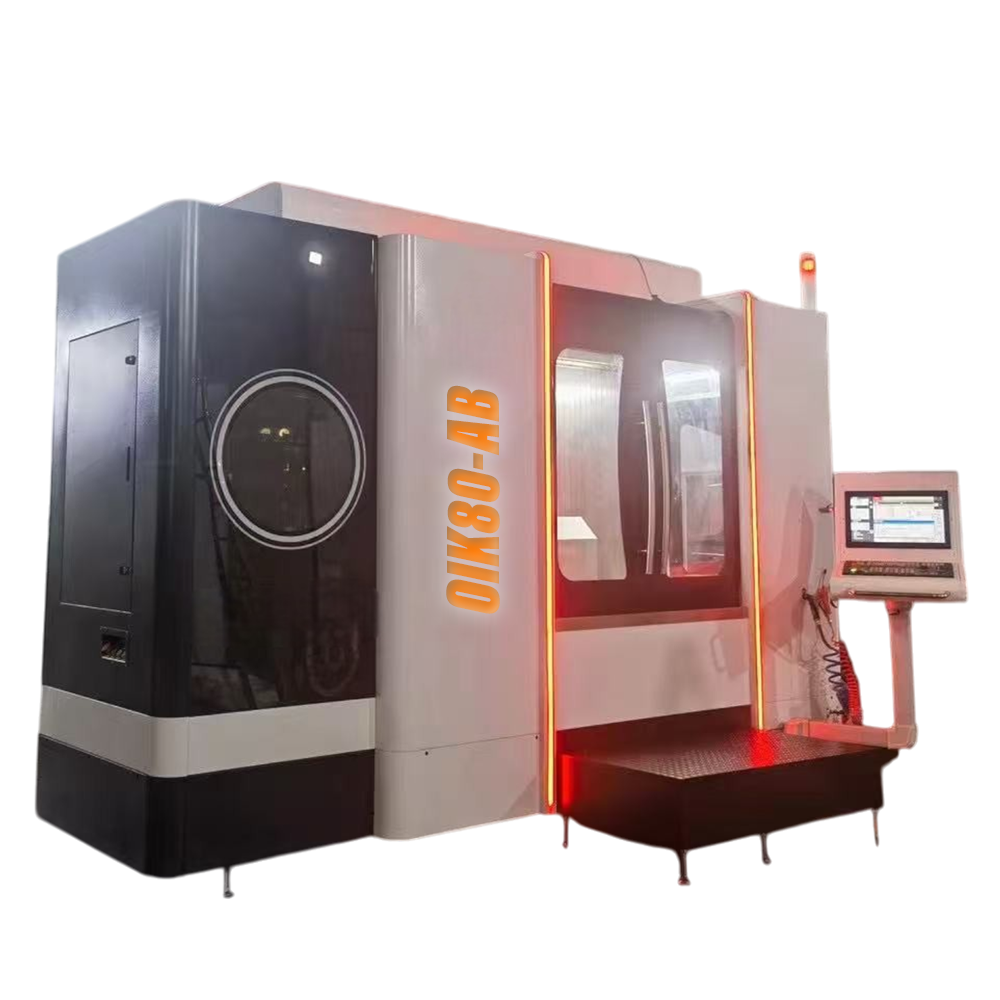

Five-Axis Machining Center

Discover the innovative design and advanced technology behind our CNC machines. Our high-bridge design ensures effective isolation, while the integrated frame gantry base offers outstanding structural stability. Experience the benefits of our advanced transmission system and space-optimized design, enhancing your production efficiency.

Innovative High-Bridge Design

Our high-bridge design optimizes the operating environment, allowing for a wider range of machinable materials, including graphite and ceramics. This design ensures effective isolation between the motion transmission mechanism and the workpiece processing area.

Outstanding Structural Stability

The integrated frame gantry base provides excellent rigidity and weight, while the anti-vibration design increases natural frequency, effectively preventing resonance phenomena. The thermal symmetry design ensures processing accuracy stability.

Advanced Transmission System

Our single-screw center drive design and beam movement ensure synchronized motion, providing an excellent linkage effect that guarantees high processing quality.

Control System

Optional FANUC or Siemens

OIK80-AB

| Specification | Unit | OIK80-AB |

|---|---|---|

| Gantry switchboard vertical machining centre | ||

| Workbench specifications (W x L) | mm | 2-400×600 |

| Max. workbench load | kg | 2-350 |

| X/Y/Z axis coordinate travel | mm | 500/400/450 |

| Distance from spindle end to | mm | 120~570 |

| workbench surface | ||

| X/Y/Z axis rapid movement speed | m/min | 30/30/30 |

| Feed cutting speed | mm/min | 5~8000 |

| Spindle speed range | r/min | 60~12000 |

| Spindle motor power (nominal/intermittent) | kW | 5.5/11(S1/S3-15%) |

| Spindle output torque (nominal/intermittent) | Nm | 26.3/70(S1/S3-15%) |

| Tool holder type/maximum tool weight | kg | BT40 /7 |

| Tool magazine capacity/form | 2/16/24 optional | |

| Positioning accuracy/repositioning accuracy | mm | 0.010/0.005 (VDI/DGQ 3441 standard) |

| Machine size:L*W*H | mm | 1450×4000×2000 |

| Machine.Weight approx. | kg | 8000 |